June

2023

Sustainable Manufacturing: Shaping a Greener Future, One Company at a Time

Sustainability is an increasingly prominent topic in the world and in production as well. The rubber industry is not far behind and keeps up with the right ecological decisions. BOGUMA has been supporting ecology in several areas of production since its beginning, and it is time to introduce you to the ways in which we are approaching more sustainable production.

You may have noticed an increase in attention directed towards a more sustainable way of production worldwide in recent decades. Slovakia, and thus the place where our production hall is located, also supports steps that lead to the reduction of air pollution and overall waste production as a result of the manufacturing of our products. These are often complex changes that, in addition to time, require financial resources and the involvement of several collaborators. But mainly, these changes can only work if we accept responsibility for our manufacturing and its possible negative consequences for the environment.

Under the term "sustainable manufacturing" you can imagine, for example, the use of natural resources, switching to LED lighting, recycling, or efforts to reduce waste by utilizing all parts of production materials. But it is also about sustainability in cooperation with suppliers or clients: trying to find suppliers who are located near the company (if conditions allow doing so) and choosing business partners who also implement a more sustainable operation of their company.

Advantages of sustainable production

Companies that are not afraid to step in the right direction experience many benefits that clearly outweigh possible initial negatives. These are, for example:

1. Cost savings

Switching to more sustainable practices can lead to lower costs in the long run. Energy-efficient technologies, waste reduction, and recycling initiatives can help minimize resource consumption, resulting in lower utility bills, waste disposal costs, and material costs.

2.Mitigation of risks

Sustainable production practices can help reduce business risks associated with resource scarcity, price fluctuations, and regulatory changes. By diversifying energy sources, optimizing the use of materials, and investing in renewable resources, companies can increase their resistance to market fluctuations and secure their operations for the future.

3.Innovation and long-term viability

The pursuit of sustainability often encourages innovation and creative problem-solving. It pushes companies to explore new technologies, develop more efficient production methods and invest in research and development. These efforts can result in long-term business viability, resilience, and competitive advantage in a rapidly changing market.

Overall, adopting sustainable manufacturing practices offers a range of benefits. However, it should be added that more sustainable production is not a uniform template for all companies. The specific procedures for such manufacturing may vary depending on company size, location, and available resources.

Sustainability in BOGUMA

In our company, we understand the importance of more ecological production and distribution, which leads to an improvement in the level of the environment, therefore we are actively dedicated to the continuous improvement of our processes. Some of the following activities have been part of our company since its inception and others we have introduced only recently.

Waste recycling

One of the best-known and most common ecological practices is, of course, the recycling of waste generated during the production of products. It is an advantage that the remaining scraps of rubber do not end up in a landfill and can be used for further use. How? In cooperation with an external company, we can grind the cuttings, i.e. waste from production, and then use them as a suitable filler for artificial lawns, which are suitable for long-term use, for example, on sports fields.

Our rubber waste gets a second life as a part of synthetic grass.

However, we focus not only on the waste caused by the production of our products but also on the waste that may arise from the activities of our employees. This is mostly the result of normal actions that cannot be avoided during the day, so we encourage our employees to take care of the correct sorting of waste.

Recycling of waste produced during manufacturing caused by day-to-day activities of our employees is a must

Natural materials

Another point that we have already mentioned is the use of natural materials. At BOGUMA, we use products made from natural materials mostly in cleaning processes. This is, for example, a brush for cleaning cylinders, which is made of agave sisal cactus, we also use smaller brushes for cleaning with horsehair bristles or sorghum brooms for larger areas with dirt.

We have been using natural materials since the beginning of the company's operation, as they are an available commodity in our country, and thus we have easy access to them. They also have a longer lifespan compared to artificial materials, so there is no need to change them often.

As you can see, we use sorghum brooms and brushes from horse hair.

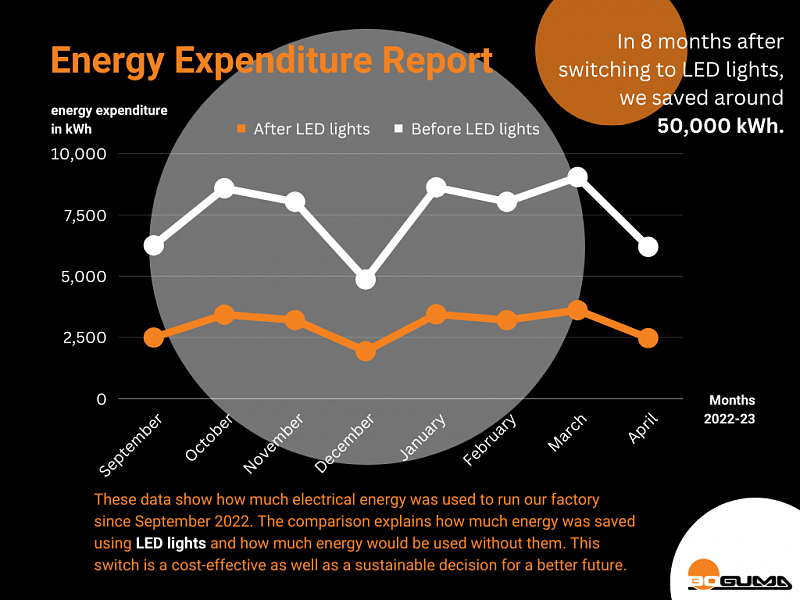

LED Lighting

As we mentioned in one of our posts on LinkedIn, in 2022 we changed the lighting throughout the company and switched to LED lights. It is a change that brings us benefits not only in reduced electricity consumption but also helped us reduce the costs of its financing, which we can further invest in other ecological changes.

This graph shows a comparison of our energy expenditure before and after using LED lights

Sustainable exterior

We promote sustainable practices not only inside the company but also try to implement more ecological solutions in its surroundings. Recently, for example, it was necessary to renovate the facade of our production hall. Instead of demolishing and completely rebuilding, we decided to restore the facade by repainting it. We avoided replacing the material with plastic. Not only because of the unwanted transition to non-ecological material but also to preserve and remember the history of the building in which we are based. We believe that the original appearance of the building is part of us to this day and we do everything to keep it that way.

Comparison of our facade during and after renovation that didn't require a complete rebuilding.

In the spirit of greener decisions and clean air, we planted different types of trees around the building just a few weeks ago. We live in an industrial part of the city, so greenery is rather a rarity. We therefore decided to bring back a bit of nature to our surroundings and together with our colleagues we planted several pine and spruce seedlings. Later, we plan to add more to them and continue to beautify our surroundings and at the same time support the environment.

This is one of our numerous trees that help bring nature back to an industrial environment.

The main purpose of this article was to show you that ecological solutions do not have to be financially demanding and they bring tremendous benefits not only for individual companies but for the whole world. We are glad that it is becoming easier to support "green" changes in our country and we hope that you will be inspired to take similar steps.

If you would like to share with us the ways in which ways your company supports the environment, do not hesitate to contact us at info@boguma.sk or leave us a comment under our LinkedIn post.

Electrical Insulating Blanket - Unnecessary Purchase or Today's Standard?

Electrical Insulating Blanket - Unnecessary Purchase or Today's Standard?

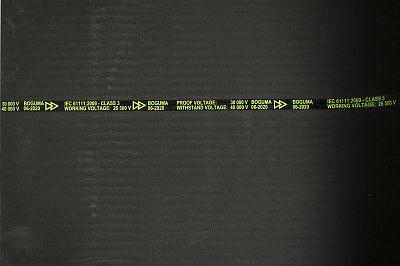

IEC 61111:2009 standard - why it pays off to invest in properly tested products

IEC 61111:2009 standard - why it pays off to invest in properly tested products