June

2023

Electrical Insulating Blanket - Unnecessary Purchase or Today's Standard?

Electrical Insulating Blanket belongs to the category of electrical insulation products that protect workers' lives in various industries when working with live electrical parts, thanks to their properties. We recognize its rise, but not everyone realizes its importance. Is it the right time to invest in this protective product?

Our Electrical Isolating Blanket - suitable for various environments

First and foremost, we want to emphasize the importance of protecting workers when working with live electrical parts. It is well known that mishandling of electric current is one of the most common workplace hazards, especially in the construction industry, causing serious injuries and, in some cases, even death. According to the Electrical Safety Foundation International (ESFI), electrical accidents and workplace fatalities remain a concerning issue. From 2011 to 2020, ESFI statistics revealed an average of 1,001 electrical fatalities per year, with the construction industry being particularly vulnerable. These accidents range from electric shock injuries to burns and even fatalities caused by the electric current. It is alarming to find that, on average, there were 156 fatal electrical accidents each year during the studied period. These tragic events highlight the need for strict adherence to electrical safety protocols in the workplace. Employers must ensure training employees on electrical risks, implementing proper safety measures, and complying with relevant electrical regulations. Regular inspections, maintenance of electrical systems, and the use of personal protective equipment can significantly reduce the risk of electric shock. Remember that knowledge of and compliance with electrical safety is essential not only for protecting workers' lives but also for maintaining a productive and safe working environment. (Note: The information was obtained from the ESFI statistical office and focuses on the United States)

In one of our previous articles, we mentioned one type of electrical insulation product, Electrical Insulating Matting (EIM), which is suitable as an insulating layer, particularly for floors. However, if you need protection from smaller electrical parts, there is a better alternative to EIM, and that is the Electrical Insulating Blanket (EIB). Keep reading to learn about all the uses and advantages of EIB that can save lives.

Origin and Structure of EIB

The Electrical Insulating Blanket is an essential part of protecting workers from injuries caused by contact with live electrical parts. Its origin dates back to the 19th century when the vulcanization process was discovered. This process involves heating rubber with sulfur to create a more durable and flexible material. Later, this process was applied to the production of rubber blankets that could be used to protect workers from electric shock.

Two centuries have passed since its invention, and the blanket has been transformed into many forms. Our company's rotocure press Electrical Insulating Blanket is no exception. It was specially developed based on the request of one of our loyal customers who sought a higher quality of this product. The initial development started in 2010, and we obtained certification within a year of the first trials. The final product was refined over 3-4 years to its current form. It is evident that producing a high-quality durable product requires time for testing and continuous improvement over a long period.

Although we can specifically talk about our product, the base of the Electrical Insulating Blanket is a generally accepted standard without which it could not pass the necessary tests. The material is specially made from a combination of synthetic and natural rubber compounds, which makes it highly resistant to tearing and puncturing. For safety purposes, the blanket is produced in orange color, which enhances visibility and contributes to additional protection. These characteristics are supplementary features accompanying the fundamental need for electrical insulation, and they are commonly used in various work areas.

Where and How to Use EIB

Thanks to its insulating and other protective properties, the Electrical Insulating Blanket is a useful product applicable in many industries working with live electrical parts.

Automotive Industry

The first area of application we must mention is the automotive industry, specifically vehicle and electric vehicle repair shops. Workers can use it to cover car batteries during car service, preventing direct contact with electrically conductive objects. Because our blanket is also resistant to acid, it can prevent acid from reaching the surface of the car battery. The blanket is highly durable, so you don't have to worry; its electrical insulation capability will not be compromised, successfully preventing contact between acid and human skin.

An example of one of many uses of EIB

Electrical Maintenance

Another useful application of the insulating blanket is observed in live electrical line maintenance. When working on electrical lines, such as electrical poles, workers often have to reach a height of approximately 9 meters, where any additional weight becomes an unwanted burden. Therefore, besides the previously mentioned characteristics of EIP, it is important to highlight the lightweight material, making it easy to handle without posing a significant physical toll at a weight of 1.6 kg/m2.

The blanket is also tested for ozone resistance when used outdoors on poles. Insufficient protection and prolonged exposure to sunlight can lead to fires. However, even in such cases, the sheet retains its electrical insulation properties.

Maintenance of electrical components requires safe equipment at all times

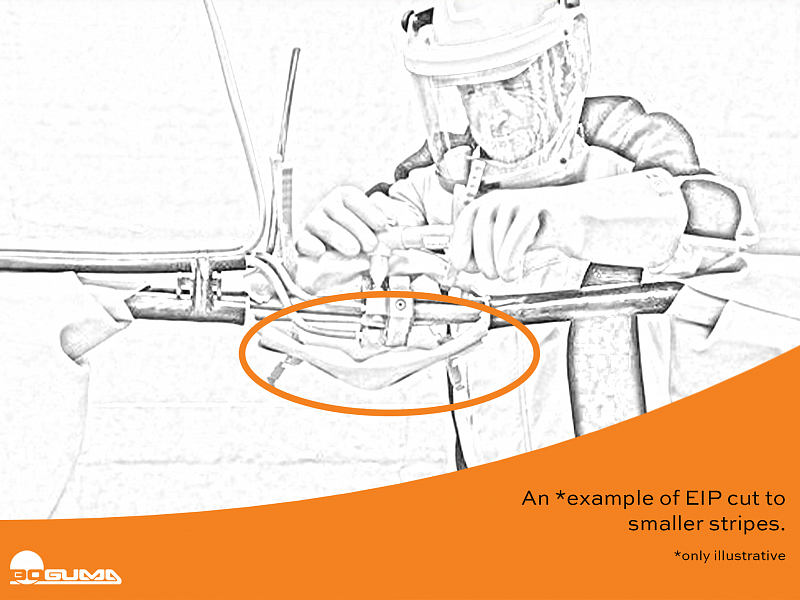

One blanket can become much more

One of the many advantages of the blanket is its versatility. While we commonly supply it in rolls with widths of 1m and 1.2m, it can be cut into approximately 20-centimeter-wide strips. This brings us to another possible use of EIP. With the strips equipped with a dry zipper on both sides of the bottom surface, electricians and other workers can use them to cover smaller electrical components. Securing them with a velcro strip ensures increased safety when working with live electrical parts, preventing accidental contact with electrical lines and the occurrence of sparks.

Lastly, we would like to emphasize the strength of the insulating sheet, which is a desirable property in any work area, hence the general mention. With a minimum tensile strength of 12 MPa and a minimum resistance against tearing of 300%, you don't have to worry about the blanket becoming damaged easily. However, proper care according to our recommendations is still necessary.

Custom-made cuts of EIB always come in handy

Lastly, we would like to emphasize the strength of the insulating sheet, which is a desirable property in any work area, hence the general mention. With a minimum tensile strength of 12 MPa and a minimum resistance against tearing of 300%, you don't have to worry about the blanket becoming damaged easily. However, proper care according to our recommendations is still necessary.

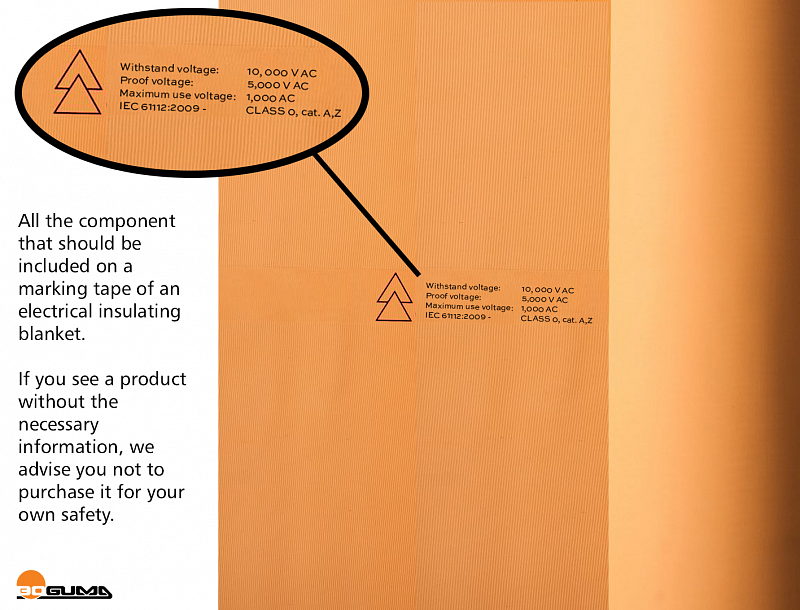

Certification and Maintenance

This type of blanket is a specific electrical insulation product, which means it must be certified according to a different standard than IEC 61111:2009 for electrical insulating mats. The blanket is tested according to the IEC 61112:2009 standard for Class A and Z. It has been available since 2014. The A and Z markings indicate that the EIB is resistant to acids and ozone, which is advantageous for many industries, as mentioned in the previous examples. The specified working voltage according to the IEC 61112:2009 standard for Class 0 sheet is 1000 V. The marking is applied permanently and indelibly by vulcanizing the marking tape along the entire length of the blanket, similar to electrical insulating mats.

Be careful and do your research before investing in EIB. Certification is necessary for safety.

Although you receive a 100% tested and inspected product, user negligence can lead to damage. To prevent unnecessary errors, avoid contact of the sheet with oil, acetone, and similar solvents as it is not resistant to them. However, common dirt can be removed by manual washing with simple soap that does not contain chlorine or solvents. The blanket can be safely soaked and reused after drying.

The warranty for this product is one year, although the material could last up to 5 years with regular inspections by a qualified technician. An experienced worker can assess whether a blanket can continue to be used safely or if it’s no longer usable. If it is determined that the blanket can no longer be used for safety reasons, it can be disposed of by grinding, as it is made from standard rubber materials, despite its specific properties.

Thanks to its properties, the insulating blanket is undoubtedly a beneficial investment that greatly enhances the safety and quality of workers' lives. It is no surprise that its increasing popularity is being noticed in various countries, such as Belgium and the United Kingdom. We can therefore safely proclaim that Electrical Insulating Blanket should be today’s standard in all respected industries.

Have you discovered something new or have you been reaffirmed in your correct safety decision? Let us know at info@boguma.sk or leave a comment on our LinkedIn post. We would be happy to connect with you.

From The Beginning Until BOGUMA

From The Beginning Until BOGUMA

Sustainable Manufacturing: Shaping a Greener Future, One Company at a Time

Sustainable Manufacturing: Shaping a Greener Future, One Company at a Time