April

2023

IEC 61111:2009 standard - why it pays off to invest in properly tested products

IEC 61111:2009 is almost as important as having breakfast in the morning but not as controversial among dietitians. Have a look at this article to become an informed customer, who is not afraid to expect only the best quality from your suppliers.

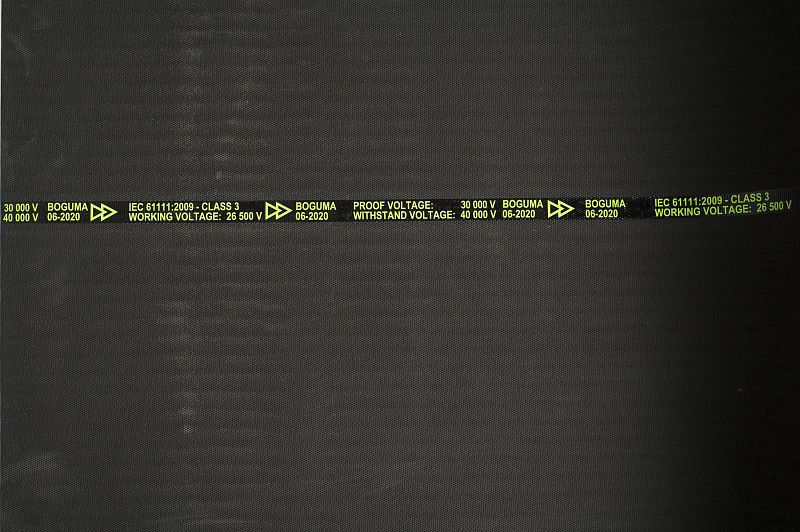

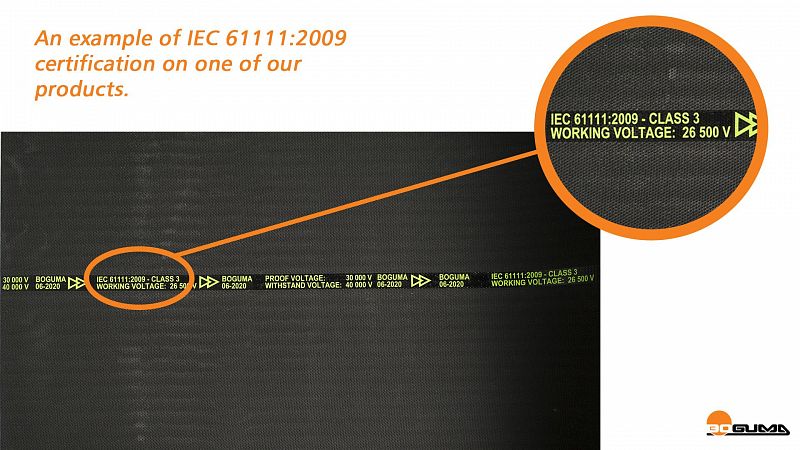

An example of IEC certification on a marking tape.

In one of our previous articles, you could find all the necessary information about Electrical insulating matting and how to decide which type is the right choice for you according to various aspects. We have mentioned a set of criteria that, among many others, also included the IEC 61111:2009 standard. This time, we will look more closely at the mentioned standard and all its perks. If you are not entirely sure what the standard represents and why it is important to only invest in products that have this certification, read on.

The origin and purpose of IEC 61111:2009

As the name suggests, The IEC 61111:2009 standard was created in 2009. It cancels and replaces the first edition, published in 1992. It was constituted by the International Electrotechnical Commission (IEC), a non-profit organization that develops and publishes international standards for all electrical, electronic, and related technologies. The IEC was founded in June 1906 in London, UK. Its mission is to promote the safe and effective use of electrical and electronic products and technologies worldwide.

The logo of International Electrotechnical Commission (IEC)

IEC 61111:2009 provides a set of requirements for electrical insulating matting used in low-voltage as well as high-voltage installations. It specifies the minimum requirements for manufacturing, testing, and performance of electrical insulating matting, which is essential to protect workers from electrical hazards. One of its main advantages is that it can be used across borders, ensuring that the products are safe and reliable for workers around the world.

The standard specifies the

- thickness

- electrical resistance

- mechanical properties

of electrical insulating matting, among other requirements, to ensure that the matting can withstand the rigours of use and provide effective protection to workers.

Electrical insulating matting can be used in a wide range of installations from low-voltage to high-voltage to protect workers from electrical hazards. The matting is placed on the floor around electrical equipment and provides a barrier between workers and the ground, preventing electrical current from passing through their bodies. It must be able to withstand even high voltage and electrical current without degrading or losing its insulating properties.

An illustration showing one of the uses of Electrical insulating matting that requires IEC certification.

Certification to the IEC 61111:2009 standard is essential for companies that manufacture or supply electrical insulating matting. When you encounter a company that offers electrical mats without such certification it is advised to avoid purchasing products from them. We highly recommend not investing in such products in order to minimise the risk of endangering the health of your employees and colleagues in high-voltage workspaces.

Advantages of IEC 61111:2009

Purchasing a product that complies with this IEC standard brings a plethora of advantages to its users. Here are the main ones.

1. Safety

Safety is the number one priority when working with live electrical parts. The IEC 61111:2009 standard ensures that the products are safe and reliable for workers around the world. Products that comply with this standard provide assurance that they will protect workers from electrical hazards.

2. Quality

The easiest way to find out if a product is of the required quality is IEC certification. It demonstrates that the product meets the highest quality standards. The standard specifies the thickness, electrical resistance, and mechanical properties of electrical insulating matting, among other requirements, to ensure that the matting can withstand the rigors of use and provide effective protection to workers.

3. Compliance

IEC certification is applicable internationally which is often a requirement for companies that operate in multiple countries. Purchasing products with IEC 61111:2009 certification ensures that the products comply with a globally recognised standard, making it easier for companies to meet their compliance obligations.

A close-up of IEC certification on a marking tape.

Disadvantages of products without IEC 61111:2009

Unsurprisingly, there is no downside to purchasing products with IEC certification, however, there are various negatives to obtaining products without one. It is not safe to buy products without IEC 61111:2009 certification because of:

1. Unknown quality

Products that do not have certification to the IEC 61111:2009 standard may not meet the minimum requirements for manufacturing, testing, and performance, potentially putting workers at risk. Without certification, there is no way to know if the product has undergone the proper testing and meets the highest quality standards. Such products may perform inadequately and might need to be replaced sooner than the standard certified products.

2. Lack of assurance

Without certification to the IEC 61111:2009 standard, there is no assurance that the product will provide effective protection to workers from electrical hazards. Workers may be at risk of electrical shock or electrocution if the product does not meet the necessary requirements for electrical resistance and mechanical strength.

3. Non-compliance

Companies that purchase products without IEC 61111:2009 certification may be at risk of non-compliance with local regulations and international standards. This could result in fines, legal liabilities, and reputational damage.

An image highlighting the importance of a marking tape containing the IEC certification. Do not invest in mats without IEC certification.

Proudly certified

To obtain certification to the IEC 61111:2009 standard, our products underwent rigorous testing to ensure they met the standard's requirements. The testing process involves taking samples of the matting and subjecting them to various tests to assess their electrical resistance, mechanical strength, and other properties. Our products passed the tests and were therefore certified to the IEC 61111:2009 standard. Some clients are extra cautious and require third-party testing of our products. It is an understandable precaution as everyone wants only the best for the health of their employees and we 100% agree with being safe with the highest quality products.

We are proud of the quality of our products across all fields of use and we are glad that there is a standard that helps our clients and potential customers recognise products worth investing in to ensure the safety of their workers.

We believe that every company should strive for the highest quality of their products because they affect the clients, their workspaces and workers immensely, especially when it comes to working with electrical parts. Have you learnt something new from our article? Let us know through an email at info@boguma.sk or leave us a comment on our LinkedIn post that mentions this article.

In the next our next piece, we will have a close look at another type of insulating product - Electrical insulating blanket.

Sustainable Manufacturing: Shaping a Greener Future, One Company at a Time

Sustainable Manufacturing: Shaping a Greener Future, One Company at a Time

Safety first with the right ELECTRICAL INSULATING MATTING

Safety first with the right ELECTRICAL INSULATING MATTING